No products in the cart.

Blog

Print Industry Showdown: Screen Printing Vs Digital Printing

In print media, 2 techniques reign supreme – screen printing and digital printing. Whether you’re an artist looking to bring your designs to life, a brand aiming to create custom merchandise, or simply an enthusiast curious about the print world, understanding these 2 methods can be invaluable. This blog post aims to demystify the ongoing battle of ‘Screen Printing vs Digital Printing,’ delving into their unique processes, strengths, challenges, and ideal use cases. By the end of this exploration, you’ll be well-equipped to make an informed decision on which technique best serves your printing needs.

Screen Printing Vs Digital Printing: Overview

What Is Screen Printing?

Screen printing, also called silkscreen, is a time-honored method of decorating textiles that traces its origins back several millennia.

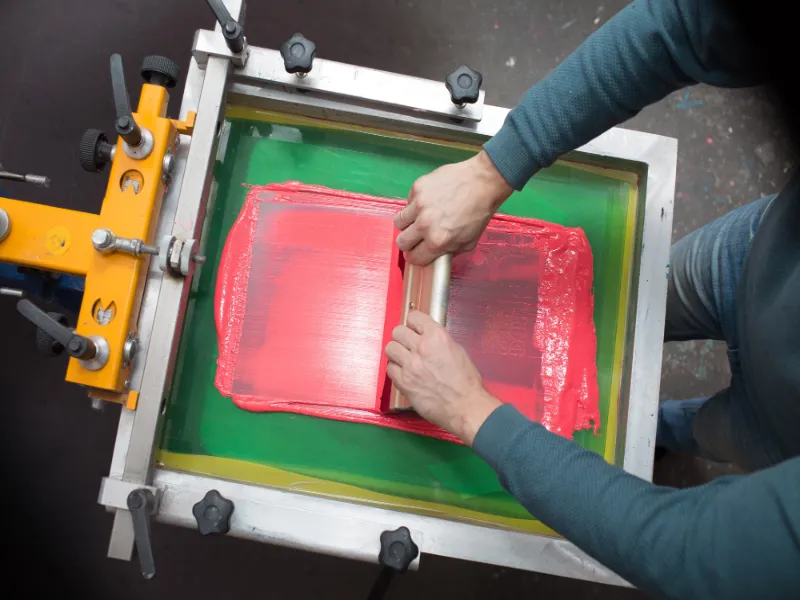

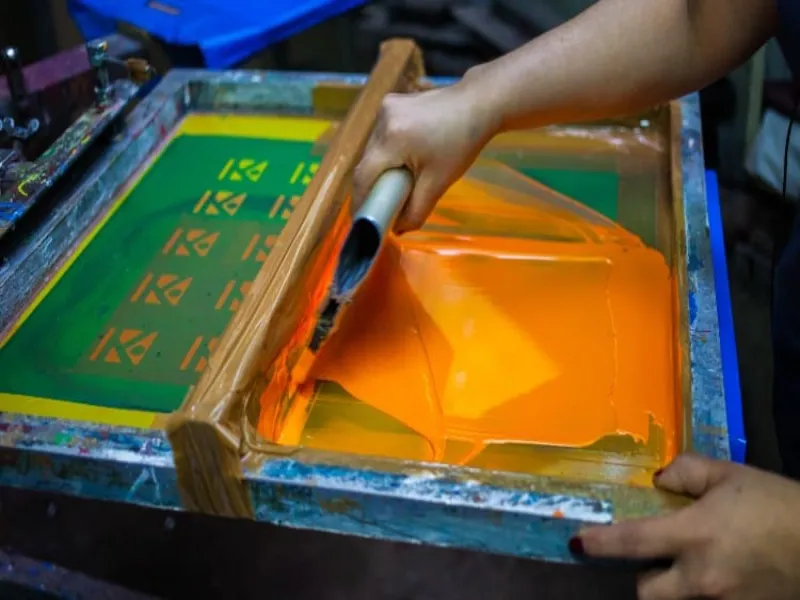

The process involves applying individual ink colors onto the textile surface via separate stencils or screens. The ink is then cured or heated to set firmly on the fabric.

- The Evolution and Efficiency of Screen Printing Technology

While the rudimentary concept of screen printing remains intact, technological advancements have greatly enhanced the precision, quality, and speed of this printing method.

For instance, modern automatic machines, such as the ones we utilize, can print over a hundred T-shirts within an hour.

This efficiency allows us to fulfill large volume orders while maintaining top-tier quality, which our clients, like the Philadelphia 76ers, can attest to. Despite the emergence of innovations like direct-to-film transfers, the demand for handcrafted screen-printed shirts remains strong.

What sets screen printing apart from digital printing?

- The Superiority of Screen Printing

Screen printing shines in scenarios involving large quantity orders, unique or oversized print placements, simple single-color designs like logos or text, the use of specialty or special effects inks, printing on synthetic fabrics such as polyester, achieving vibrant colors on darker fabrics, and situations where precise color matching is paramount.

- Advantages of Screen Printing

Screen printing is a cost-effective method, especially when dealing with large quantities. Its versatility allows for the easy repositioning of designs, facilitating dynamic and creative prints.

Despite a potentially high initial setup cost, the per-unit cost decreases significantly the more copies you order. This makes it an ideal choice if your design doesn’t change frequently.

While personalization of prints isn’t directly feasible with this method, badges can be printed and run through a digital printer to achieve personalized results.

- Limitations of Screen Printing

Screen printing may not be the most economical choice when multiple colors are involved. The method requires a considerable initial investment and limits you to one design per batch.

Also, there’s a possibility of colors bleeding into each other, which could be a drawback or a creative style point, depending on the desired outcome.

What Is Digital Printing?

Direct-To-Garment (DTG), or digital printing, has evolved significantly over the past few decades. Once a novice to the customized apparel sector, it now competes with conventional screen printing in terms of quality and cost-effectiveness.

Digital printing employs the “process” technique, which creates a spectrum of colors from just a handful (cyan, magenta, yellow, black, red, and green).

A digital machine is a large-scale inkjet printer, similar to what you might find in a home office, but engineered specifically for printing on T-shirts and other garments.

DTG printing has been a part of the printing landscape for nearly 2 decades, and the technological advancements in this time have been swift and significant. This method’s speed, affordability, and quality of prints are improving yearly.

Despite the early challenges, digital printing has achieved extensive acceptance and popularity. The entry threshold is somewhat high for most printing companies—professional machines can range from $5,000 to $200,000.

However, as far as business investments go, it’s a sound one. Companies can start accepting low-quantity, on-demand orders without the usual setup cost and effort associated with screen printing.

The majority of online on-demand printing companies currently utilize digital printers. At those places, we operate some of the most sophisticated machines available, and our volume of digital prints is increasing annually. However, we still depend on traditional screen printing for large quantities.

- Advantages of Digital Printing

Digital printing shines quickly, making it an ideal choice for those on a tight schedule. It’s also a cost-efficient solution for smaller print runs and offers the flexibility for frequent changes—ideal for personalized mail campaigns. The resulting prints are sharp, with a clean finish.

- Shortcomings of Digital Printing

Despite its advantages, digital printing has its pitfalls. One challenge is color discrepancies—the output color may vary slightly from what’s displayed on the screen.

In addition, the ink doesn’t fully permeate the paper, causing potential cracking along the folds. Furthermore, when larger prints are needed, the cost becomes significantly higher than other printing methods.

So, when does digital outperform screen printing?

Digital printing excels in certain areas: it’s ideal for smaller, simpler orders (including single pieces), standard print locations and sizes, printing on 100% cotton, and designs containing lots of detail or many colors, including gradients and other photographic elements.

It’s also the preferred choice when a soft feel or lightweight print is crucial.

Screen Printing Vs Digital Printing: What Are The Differences?

Screen printing, an established method, involves applying plastic-based ink through mesh directly onto the material. This method is versatile and widely used.

On the other hand, direct-to-garment (DTG) is a recent technique that involves spraying ink onto the material, making it fast and simple, particularly for multicolored designs.

To delve deeper into the screen printing vs digital printing debate, we will dissect several critical factors, providing a comprehensive comparison of both techniques.

Screen Printing Vs Digital Printing: Vibrancy

In evaluating the interplay of color saturation and brightness, screen printing holds the edge over digital printing with its richer vibrancy.

Despite digital printing’s notable progress, it offers a less luminous outcome. For designs that you desire to stand out prominently on a shirt, screen printing proves to be the superior method.

So, let’s check the differences right now:

- The Nature of Screen Printing Ink

Screen printing utilizes Plastisol ink, a composite of PVC particles in a plasticizing emulsion, with eco-friendly alternatives available. This ink offers exceptional opacity, enabling a luminous white under base on darker apparel crucial for color vibrancy.

Furthermore, Plastisol inks feature the most radiant colors, including fluorescents. Top ink manufacturers provide a basic set of colors that can be mixed to create thousands of custom Pantone hues.

- Understanding Digital Printing Ink

In contrast, digital printing employs water-based inks, which, while less opaque and vibrant than Plastisol inks, are especially effective on lighter garments.

Despite the capacity of Direct-to-Garment (DTG) machines to provide a decent under base, the final result may not be as bright as that of screen printing.

However, digital printing allows for a spectrum of colors using four to 6 hues based on the CMYK color model – cyan, magenta, yellow, and black, with some modern machines adding red and green to broaden the color range.

While these colors are vibrant and saturated, they are semi-transparent, beneficial for blending but less for vibrancy. Even so, digital printing can manage most jobs without compromising saturation and brightness, making DTG-printed T-shirt designs stand out.

Screen Printing Vs Digital Printing: Color Blending

Digital printers excel in creating smooth color transitions and gradients by blending a limited number of colors. With their impressive print resolution of 1200 dpi and diffusion dither, these printers can achieve fine color details that are unnoticeable to the naked eye.

One superb example is the intricate blending of colors possible with digital printing, from subtle gradations to minute color details, including elements like smoke that gradually disappear into the shirt or the precision required for accurate skin tones.

DTG printers use water-based inks, which are more translucent than the Plastisol used in screen printing. This transparency enables easy overlapping and mixing of colors, facilitating the creation of smooth, even gradients. This gives DTG an advantage when it comes to color blending.

In contrast, screen printing relies on Plastisol to implement a method known as the “simulated process,” which blends colors using halftones.

However, this technique makes it challenging to achieve accurate color blending. Additionally, the setup process for screen printing is less efficient, particularly for smaller print orders.

Screen Printing Vs Digital Printing: Color Matching

Screen printing’s prowess lies in its unparalleled ability to replicate any desired color using Pantone shades.

This capability extends beyond the limitations of the CMYK spectrum, accommodating super-saturated hues and specialty inks. For those seeking meticulous color matching, screen printing edges out its competitors.

This accurate color reproduction is particularly critical for branding purposes. Numerous businesses utilize brand guidelines that stipulate specific Pantone colors. Attempting to match these colors using digital printing can result in inaccuracies or colors falling entirely out of the gamut.

While some degree of Pantone matching can be achieved with process inks, and certain DTG manufacturers purport to provide Pantone matching, these claims hold only within the gamut.

This constraint implies that the most vivid, luminous colors may not match as expected. This shortfall does not affect screen printing, which possesses the unique capability to print every conceivable hue.

Another factor complicating color matching in digital printing is the possibility of the shirt’s color seeping through if the under base is insufficiently opaque.

This issue is especially pronounced on darker and brightly colored shirts. Thus, for exact color matching in line with your brand, screen printing is your go-to technique.

Screen Printing Vs Digital Printing: Details

In a detailed comparison between screen printing and digital printing, it’s evident that digital printing outperforms the reproduction of intricate elements.

This technique can handle and consistently reproduce the smallest aspects of a design, including fine lines, small text, textures, and minuscule elements.

On the contrary, screen printing, while robust and reliable, struggles with intricate detailing. Therefore, we take extra care while working on screen-printing assignments that involve detailed aspects.

Sometimes, we suggest customers slightly modify their designs, such as enlarging the text size, to ensure the best outcome.

In scenarios where an image involves photographic elements or gradients like fades and blends, screen printing employs halftones, which are minute dots.

If you’ve ever scrutinized a comic book using a magnifying glass, you might have noticed these dots. While these dots become visible upon close inspection on a T-shirt, they help maintain the design’s integrity.

Digital printing also deploys halftones. However, the advanced technology of digital machines, printing up to 1200 DPI and utilizing diffusion dither, sets it apart.

This frequency-modulated halftone method might occasionally produce a grainy appearance, but it assures a far superior reproduction of fine details than its screen printing counterpart.

Screen Printing Vs Digital Printing: Durability

The longevity of a print’s quality can be a significant concern with Direct-to-Garment (DTG) printing, which has wrestled with this issue since its inception. Digital prints in the past would begin to fade after a mere 10 washes.

However, today’s advanced digital prints can endure numerous washes without losing vibrancy. On the other hand, screen printing is renowned for its durability, provided the process is executed correctly.

Misapplication or improper ink curing can lead to the fading or breaking down of a Plastisol print. Nonetheless, many of us own a screen-printed shirt from a decades-old family gathering that has outlasted the event’s recollections.

Screen Printing Vs Digital Printing: Comfort And Feel

If you covet an ultra-light, barely-there print on your shirt, especially when the fabric is dark or the design is rich in colors, digital printing is your best bet. This technique sprays ink onto the fabric, leading to less ink accumulation, enhanced flexibility, and improved breathability.

The concept of comfort in this context encompasses several aspects:

- The fabric’s “drape” or flexibility. Prints that are too heavy may stiffen the fabric and give it a plastic-like feel.

- The print’s breathability. Excess ink can block the fabric’s fibers and result in a “sweat patch,” which can be unpleasant, especially during physically demanding activities like a summer 5K run.

- The print’s weight. Overly thick ink can drag down the part of the garment where the print is located—something to bear in mind with today’s popular lightweight blends.

- The print’s texture. Ideally, it should not be rough to touch or cause skin irritation.

In the screen printing industry, this tactile experience is often called the “hand.” Requests for a “soft hand” typically involve discharge or water-based ink.

However, it’s also possible to achieve this effect with Plastisol by using an additive to thin the ink, making it more lightweight and smoother on the shirt.

Screen printing techniques, such as the “distress effect” or vintage look, can further soften the hand by minimizing the ink’s surface area, making it more flexible. However, this style is unsuitable for all designs and is typically offered as an optional customization for certain orders.

Plastisol screen printing ink generally produces a heavier print, contributing to its durability. But for superior comfort and feel, digital printing takes the crown.

It’s worth noting that using discharge and water-based inks in screen printing can result in prints with virtually no “hand” (or ink feel), with discharge on its own leaving no ink deposit.

However, these techniques are not compatible with all garments and are classified as specialty inks. For this article, our comparison focuses on traditional Plastisol screen printing and direct-to-garment (DTG) digital printing.

Screen Printing Vs Digital Printing: Versatility

Regarding printing versatility, which encompasses the ability to print on a range of textiles, garment styles, and placements, screen printing takes the lead with its flexible and manual operation. However, digital printing has limitations:

- Fabric Limitations of Digital Printing

Digital printing technology has limitations, as it cannot print on all types of fabrics. The most compatible fabric for digital printing is 100% cotton, and while newer systems claim to print on various fabrics, they are not yet widely adopted in the industry.

Digital printing struggles with 50/50 blends, underperforms on polyester and is incompatible with moisture-wicking fabrics without special treatment. In contrast, screen printing is efficient on cotton, blends, polyester, canvas, denim, and even performance and moisture-wicking fabrics like rayon.

- Color Challenges in Digital Printing

Digital printing also struggles with fabric colors. Issues such as dye migration, where the dye from the garment bleeds into the ink and alters the print color, are common.

Printing on fluorescent colors is particularly problematic for digital printing. On the other hand, screen printing is color-agnostic and works well on any garment color.

- Product Style Limitations of Digital Printing

Digital printing is best suited for basic products like T-shirts and hoodies. For more complex products like hats or specific garment types (like women’s cuts, smaller items, and unique fashion brands), digital printing requires specialized platens to fit the garment, limiting its versatility.

Screen printing, with its wide range of available platens, offers greater flexibility and fewer restrictions.

- Print Location Restrictions of Digital Printing

In some cases, direct-to-garment printing may not achieve specific print placements. For example, digital printing may struggle to place the logo 1″ from the collar of an upper back location. Screen printing, however, is less limited.

Provided the garment can be positioned on a platen, it can be screen-printed. This includes pant legs, hoods of hoodies, on-pocket prints, and side prints. Thus, for jobs requiring versatility, screen printing emerges as the preferred choice.

Screen Printing Vs Digital Printing: Consistency

In T-shirt printing, achieving a uniform output is key, a challenge effortlessly tackled by digital printing. The digital nature of DTG offers excellent consistency as it processes and prints the design directly on the fabric, eliminating most variables.

Conversely, while screen printing can yield consistent results, it requires impeccable setup and identical execution for every piece – a demanding task we confront daily.

Screen printing is subject to numerous variables, from screen tension, mesh choice, and ink viscosity to dot gain, flash dry temperature, squeegee pressure, sharpness, and angle, not to mention registration. Even the smallest deviation in these factors can significantly alter the final product.

Thus, when uniformity is paramount, the choice leans toward digital printing. Its precision and functionality make it an ideal solution for maintaining consistency in T-shirt printing.

Screen Printing Vs Digital Printing: Special FX Inks

The domain of special effects printing is a testament to creativity and innovatively enhancing print dimensions.

This realm extends beyond mere colors and patterns, offering an assortment of special inks and additives that can create effects from raised textures to sparkly finishes and even glow-in-the-dark capabilities.

Being limitless in its scope, this field allows for numerous combinations, primarily governed by creativity and budget.

Exploring the variety of special inks, we find discharge, an ink that chemically eliminates the dye from the fabric. Puff is a unique additive that expands during curing, providing a soft, raised texture.

Fluorescent inks, often called ‘day glow,’ are strikingly bright, neon colors. Metallic inks, generally in gold, silver, or copper, appear glossy. Glitter inks incorporate glitter particles to add sparkle and are frequently paired with a transparent gel.

The glow-in-the-dark ink, which is almost transparent, lights up in the dark once activated. Lastly, Shimmer ink gives a distinctive shimmering, iridescent shine. This list, though not exhaustive, covers the most common types.

The world of unique inks and additives is expansive, and it is fascinating to conjecture the inventiveness and testing that goes into creating them.

Screen printing’s unique ability to enhance T-shirt designs with specialty inks can significantly boost its retail value. Although digital technology has attempted to incorporate specialty inks, it hasn’t been as successful or readily accessible as screen printing.

Screen Printing Vs Digital Printing: Popularity

Screen printing has long been the champion in the realm of custom tee printing, standing unrivaled in the perks that it offers – striking ink vibrancy, impressive durability, and cost-effectiveness. But why does its popularity matter?

Consider this: if you’re procuring shirts for your team, giveaways, or even for resale, it’s wise to choose what’s favored by the majority to ensure satisfaction. The association between T-shirts and screen printing is strong in people’s minds.

In the future, should digital technology advance and become widespread enough that the average person cannot discern a difference, the popularity factor may cease to matter. However, until such a time, screen printing continues to reign supreme in custom T-shirts.

Screen Printing Vs Digital Printing: Which Is Better?

When deciding between screen printing and digital printing, the optimal choice often hinges on several factors related to your specific needs.

The aesthetic differences are clear; digital printing offers a high-resolution, crisp, and detailed output, whereas screen printing imbues the product with a softer, more traditional, somewhat vintage feel. Each method has its merits, and the right one for you will depend on various aspects.

The first consideration is quantity. Digital printing caters well to smaller print runs, while screen printing typically demands a larger minimum order. Your chosen apparel can influence the decision, too.

Screen printing offers a wider array of fabric options. In contrast, digital printing often requires 100% cotton or selected cotton blends and is limited to certain colors.

The design is another critical determinant. If you’re aiming to print photographs or highly detailed, multicolored graphics, digital printing is the best bet. However, for larger quantities, screen printing might still be feasible, albeit potentially more costly or requiring design modifications.

Price is often a deciding factor in the print method. Several factors influence the cost of both screen and digital printing. Your chosen apparel type, from value to premium, will affect the cost based on the style and brand.

Print locations, whether one or 2 (front and back for a t-shirt, for instance), will also impact your expenses.

The fabric color can sway the decision towards screen or digital printing. For screen printing on darker fabrics, an additional white layer is necessary, which comes with additional cost. The number of colors in your design can significantly affect the price of screen printing.

More colors increase the cost, but a larger quantity can mitigate this by unlocking deeper discounts.

Finally, quantity is the ultimate price dictator, especially for screen printing. The more you order, the lower your overall cost.

Quantity is, therefore, a paramount consideration when choosing between digital and screen printing. By weighing all these factors, you can select the printing method that best suits your needs and budget.

Conclusion

After researching the topic “screen printing vs digital printing,” it’s clear that both methods have unique advantages and are better suited for different requirements.

Digital printing, a newer process, allows for more precision, vibrancy, and detail as the artwork is processed by a computer and printed directly onto the product’s surface.

It also excels in durability, although it may face issues with color fading over time. This method is generally preferred for lower quantity runs or projects that require high color accuracy.

On the other hand, screen printing, a more traditional and manual method, might be more costly but has its benefits. It provides a more authentic, retro, or softer look and is great for high durability and high quantity runs, especially when a low number of colors are involved.

Choosing between the 2 depends on the specific needs of your project. If you’re aiming for a more precise and vibrant print, digital printing is the way to go. But if you’re after a more classic look and feel, screen printing would be more appropriate.